Boilers for burning whole bales of straw STEP-KC 100 - 190 kW

Type and capacity range: STEP-KC 100 - 190 kW

Use

This equipment for biomass combustion (burning whole round/rectangular bales of straw) is designed to heat small buildings (industrial facilities, municipal heating plants, agricultural buildings, operational premises, etc.). The furnace can also be adapted for burning pieces of wood.

Type of boiler

The boilers are available as warm-water type boilers and operate at maximum working pressure 2.0 bar, while the maximum working temperature is 100°C.

Boiler description

The STEP-KC boiler consists of a water-cooled furnace with a cylindrical combustion chamber and a vertical flue gas exchanger. In the front part of the boiler are circular gates that permit bales of straw to be manually stoked easily into the combustion chamber. The flue gas outlet is located at the top of the rear part. The boilers come with mandatory fittings, insulation and metal sheeting.

Fuel

The boilers can burn straw as well as wood. Specification of straw: round/rectangular bales of straw (rapeseed straw, wheat straw, hemp straw, Uteusha energy crop), max. humidity 16%, low to medium compression. Specification of wood: bulk wood with a moisture content of up to 20%. Burning sawdust and shavings is not recommended, instead automatic boilers should be used for such materials.

- STEP-KC 100 kW – Combustion in the boiler is controlled by a draught controller (direct-acting thermostatic valve), which controls the valves supplying combustion air into the furnace. Inlet openings with these valves supplying combustion air are located at the top and bottom of the front door. The boiler comes with a cooling device in case of overheating.

- STEP-KC 190 kW – Combustion in the boiler is based on forced exhaust and/or combustion air supply. The boiler is equipped with an operating temperature controller, which, once the preset values of water temperature (90 °C) have been reached, closes the inlet openings for the combustion air supply. The boiler comes with a cooling device in case of overheating.

Clearing ash and cleaning

Ash is collected from the furnace manually via the open front door using an ash scraper and loaded into a container and put aside. When burning straw, ash removal from the furnace is recommended every 7-10 days; cleaning the heating surfaces of the heat exchanger should be done every 10-20 days.

Instructions for installation

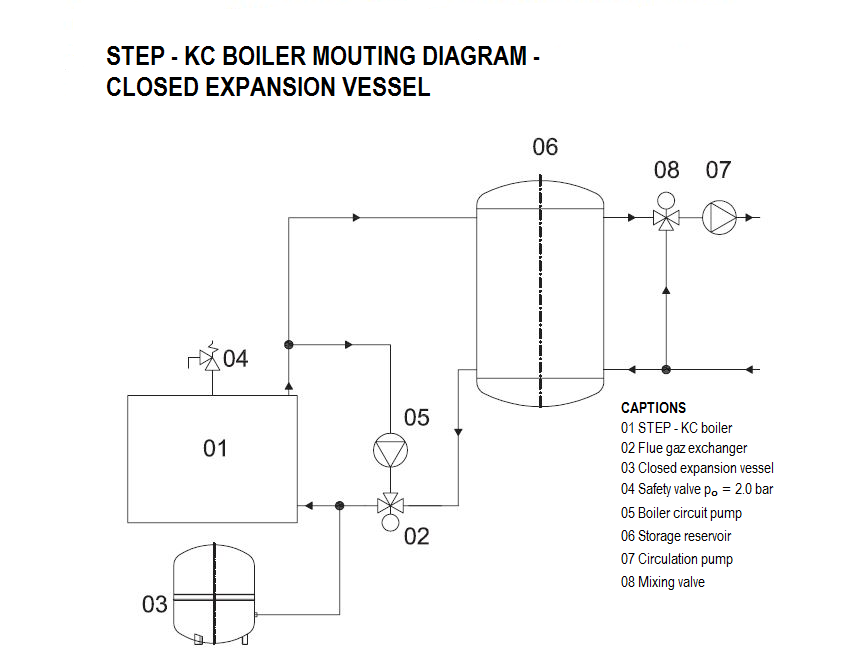

The boiler comes with instructions for installation, operation and maintenance, describing everything in detail. The manufacturer recommends installing a storage reservoir as part of the heating system (see Recommended boiler mounting diagram).

Video of installed boilers

Boiler parameters

| BOILERS FOR BURNING BALES OF STRAW, OUTPUT 100-190 kW | ||||

|---|---|---|---|---|

| STEP-KC BOILER PARAMETERS; WARM-WATER OPTION | ||||

| Boiler output | kW | 100 | 190 | |

| Standard bale parameters | Number | - | 1 | 1 |

| Diameter | m | 0,80 | 1,50 | |

| Depth | m | 1,20 | 1,20 | |

| Weight | kg | 64 | 225 | |

| Heat supplied | kWh | 151 | 530 | |

| Average output supplied; typical heating method | Stoking once per day | kW | 19 | 51 |

| Stoking twice per day | kW | 35 | 98 | |

| Maximum | kW | 75 | 190 | |

| Boiler lenght | m | 2,40 | 3,1 | |

| Boiler width | m | 1,5 | 2,2 | |

| Boiler height | m | 1,8 | 2,7 | |

| Combustion chamber diameter | m | 1,15 | 1,8 | |

| Combustion chamber lenght | m | 1,40 | 1,8 | |

| Minimum cross-section of the chimney | m | 0,30 | 0,35 | |

| Minimum effective lenght of the chimney | m | 6 | 8 | |

| Dimensions; heating water input/output | 2"/2" | 3"/3" | ||

| Boiler weight | kg | 1240 | 3100 | |

| Boiler water volume | l | 1115 | 1400 | |

| Minimum volume of the storage reservoir | l | 3500 | 9000 | |

*at nominal capacity, wood chip material humidity 20 %, and clean heat-delivery surfaces.

Recommended boiler mounting diagram: